Automatic, semi-automatic or manual machines

We always have the most suitable solution for you.

In a sector such as that of cosmetics, where the attention to the aesthetic and to the

functionality of the packaging is very high, it is necessary a great technical skill to realize

machines which can combine maximum precision and high performances. Our products

can satisfy even the most demanding customers, because they are the result of many

years of experience and investments, both in technology and in research and

development, thanks to which we can offer a complete range of customized machines and

equipments, that are precise, reliable, highly productive and well-finished even in the

smallest details.

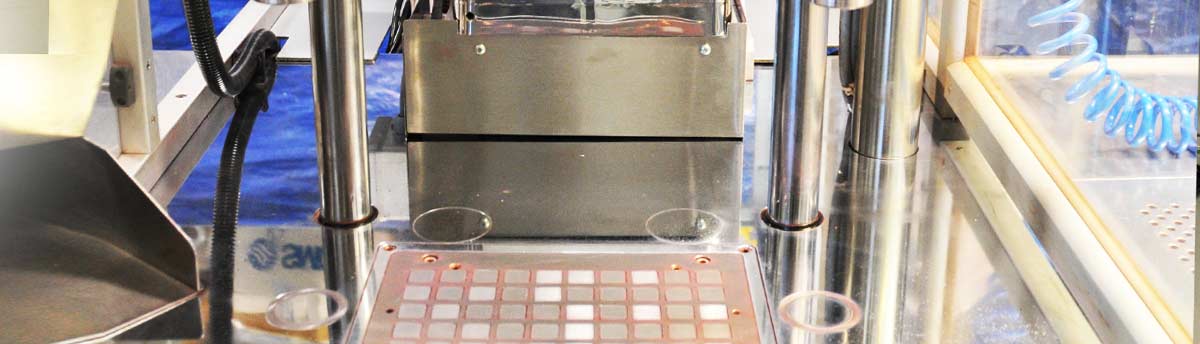

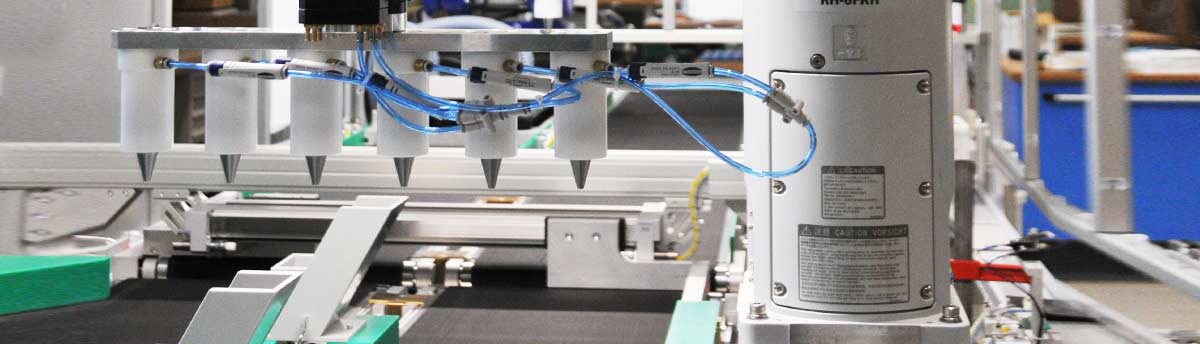

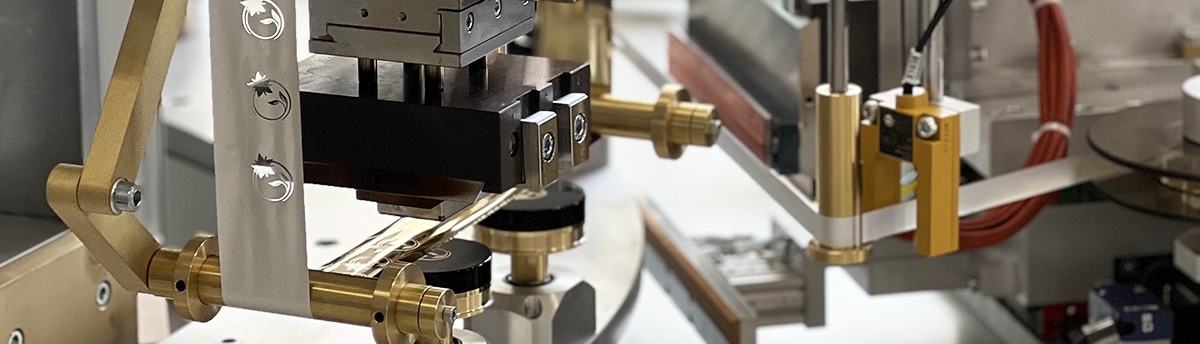

Hot stamping machines

Our core business is the projecting and realization of the hot stamping machines, a speciality in which, every time, high precision, creativity and adaptability are necessary to suit the design of the various decorations and shapes of the packaging. Our machines can execute even the most complex manufacturing such as the overmolding with internal decoration.

Given the latest needs in the cosmetics field, we have developed machines that decorate in multiple colors by equipping them with multiple decorating heads. Combined machines are also possible, therefore equipped with both flat and round decorating heads.

Types

- Flat decorating machines moved by a servomotor and ball screw and recirculation.

- Round decorating machines; the machine is equipped with decorating heads interpolated with the positioning, so as to allow a higher quality of decoration.

- Semi-manual machines; the operator has the task of feeding and operating the machine manually, but the management and decoration of the piece is automated.

After several studies and tests, we have arrived at being able to decorate a piece by involving multiple hot decorating heads in the same machine, it will therefore be possible to decorate both in the round and flat and also in multiple colors.

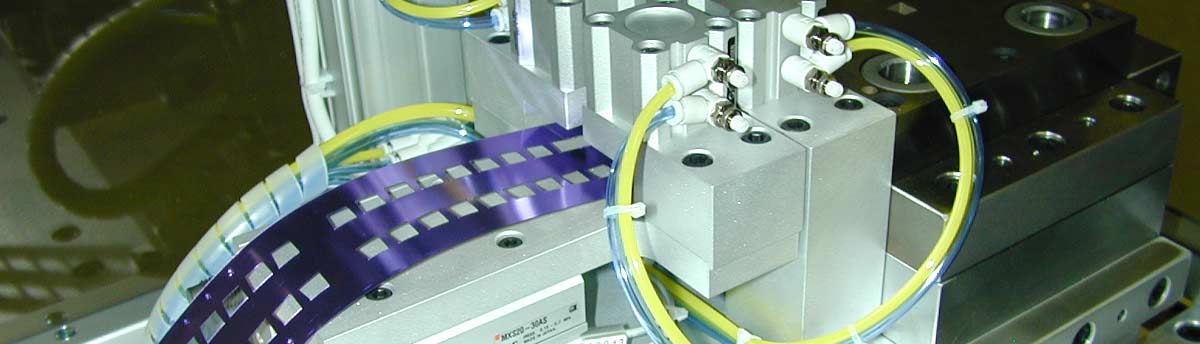

Silk-screen printing decoration machines

Our silk-screen printing decoration machines are all regulated by inverters and include the movement of the interpolated frame with the positioning and the inking spatula can be either pneumatic or electronic with brushless motors.

It is possible to create combo machines, that is, machines that are equipped with both hot decoration stations and screen printing or pad printing stations. The pieces, when they pass from one decoration to another, are oriented so as to guarantee the quality of the decoration.

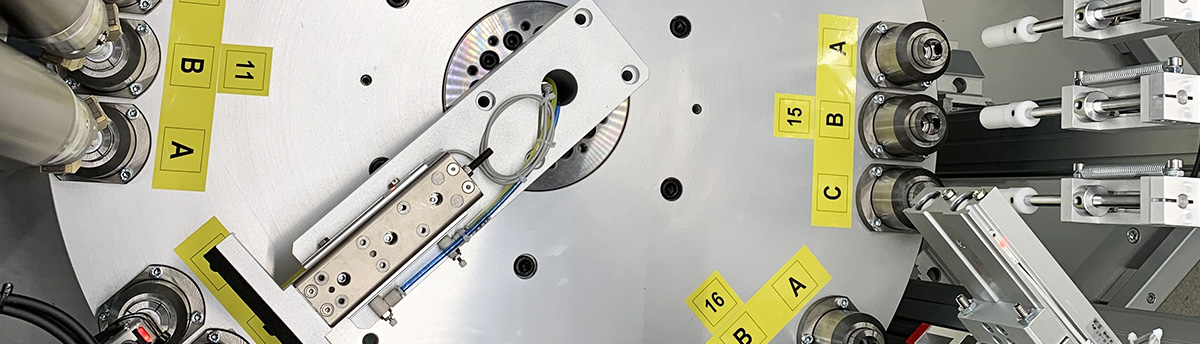

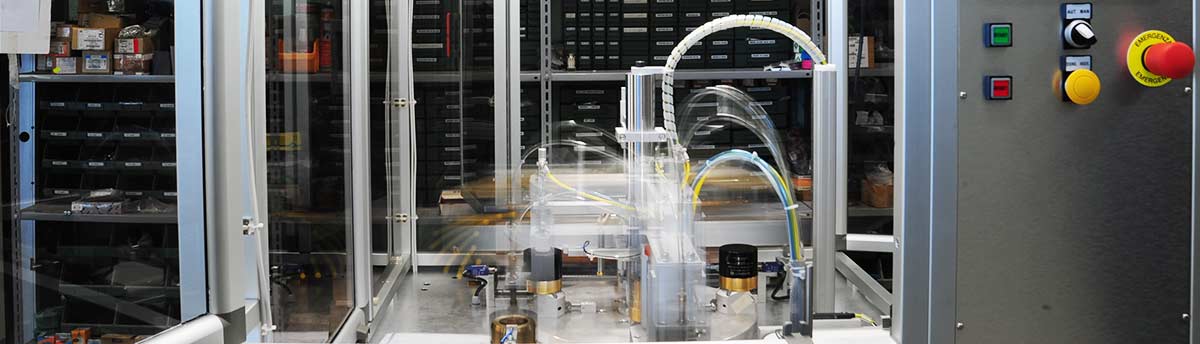

Assembly machines

The cap of a perfume bottle can be made up of even 12 pieces that have to be perfectly assembled, and, when required, to appear as a single piece, this is an example of what can be achieved with our mechanical and pneumatic assembly machines, which are automatic, with glue, ultrasounds, and vision systems.

Revamping

Revamping is a modernization of obsolete or low-productivity machinery, with the aim of giving them a second life by making them more efficient, innovative and with a low environmental impact.

Our revamping involves the creation of a new electro-pneumatic system and the replacement of the PLC, trying to maintain, however, the structural part (the table, the legs and the casing) and, possibly, other mechanical components.

The machine can be certified 4.0 and will be equipped with the most innovative components on the market. It will be like having a new and high-performance machine with a limited investment. When necessary, a new program will be created and a new safety guard will be installed, so that the new machinery is compliant. The production times are drastically reduced and, if the machine is still in use, we ensure that the machine downtime is very short.

We design the modifications, purchase all the materials, develop the new program, create and prepare all the components before the machine is delivered to us. The machine will be studied together with the customer to make it tailor-made according to his needs. The goal is to avoid the waste of still usable material and making the machine usable again to its maximum potential.

Palletizing machines

At the palletizing machines you have the possibility of installing different types of belts, based on needs, but also cooling systems, systems for pressing the burrs or control and orientation groups, all this to speed up production times and limit the occupied spaces from machinery.

Complete production lines

From when the packaging comes out of the injection press to the end of the production cycle, we will see to it. We can build complete customized production lines, including conveyor belts of various sizes. Whatever the customer's requests may be we can find technological solutions which will allow to create an outstanding product.